US, Europe & China Ductile Iron Pipe Standards: Key Differences for Engineers

1. Introduction: Why Standard Differences Are Critical in International Projects

In global water supply, municipal networks, and infrastructure construction, ductile iron pipes (DIP) are widely used due to their excellent mechanical properties, long service life, and mature construction techniques.

However, in cross-border engineering or international procurement projects, a frequently underestimated but highly impactful issue is the difference in ductile iron pipe standards across countries and regions.

These differences not only manifest in dimensions, wall thickness, or material parameters but also have continuous impacts on engineering design, procurement, construction, and long-term operation, affecting project safety, cost efficiency, and controllability.

This article systematically analyzes the core differences among the US, European, and Chinese ductile iron pipe standards and examines their practical impacts on project selection and execution from an engineering perspective.

2. Overview of Major National and Regional DIP Standards

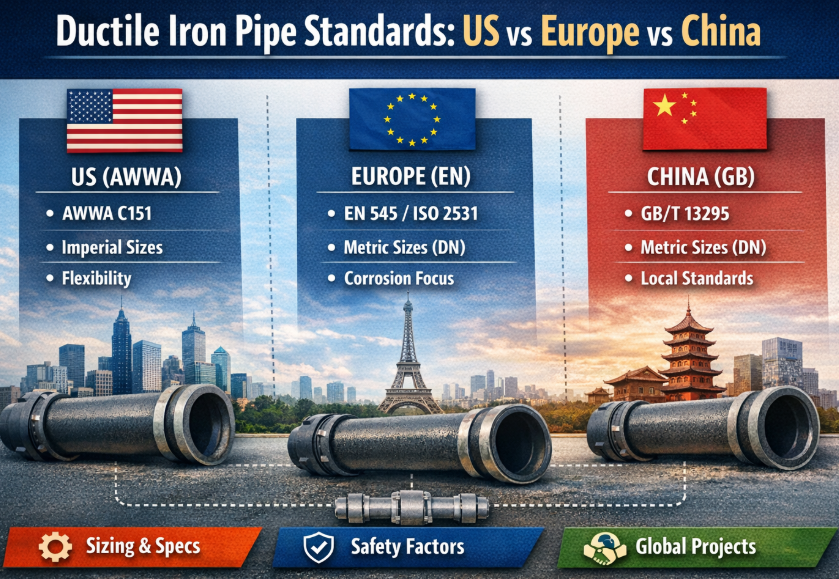

2.1 United States Standards (AWWA)

In the US, ductile iron pipes primarily follow the American Water Works Association (AWWA) standards:

- AWWA C151: Specifies pipe dimensions, wall thickness, and performance requirements

- AWWA C600: Specifies installation and construction guidelines

US standards emphasize practical engineering application, focusing on operational reliability and construction adaptability. They adopt imperial units, which differ from the metric DN system used in most other countries.

2.2 European and International Standards (EN / ISO)

In Europe and international projects, the main standards include:

- ISO 2531: International standard for ductile iron pipes

- EN 545: For potable water supply

- EN 598: For sewage and drainage systems

These standards use the metric DN system, provide detailed requirements for material performance and corrosion protection, and are especially advantageous for long-term durability in complex soil conditions.

2.3 Chinese National Standards (GB)

In China, ductile iron pipes mainly follow:

- GB/T 13295: For water supply

- GB/T 26081: For drainage and sewage

Chinese standards reference ISO/EN frameworks while adapting to domestic engineering practices, achieving good compatibility in international projects.

Table 1|Overview of Major DIP Standards in the US, Europe, and China

Region / Country | Main Standards | Standard Organization | Primary Application | Dimension System |

US | AWWA C151 / C600 | AWWA | Municipal water supply, transmission pipelines | Imperial |

Europe | EN 545 / EN 598 | CEN | Drinking water / sewage systems | Metric (DN) |

International | ISO 2531 | ISO | General international water and sewage projects | Metric (DN) |

China | GB/T 13295 / GB/T 26081 | Standardization Administration of China | Water supply / drainage | Metric (DN) |

Overall, ISO, EN, and GB standards are highly consistent in dimension systems and technical logic, whereas AWWA standards differ in dimension definitions and engineering focus, representing the most common technical divergence in cross-standard projects.

3. Analysis of Core Technical Differences

Table 2|Comparison of Core Technical Requirements (AWWA / EN / ISO / GB)

Dimension | AWWA (US) | EN (Europe) | ISO (International) | GB (China) |

Nominal Diameter | Imperial | DN Metric | DN Metric | DN Metric |

Wall Thickness Classification | Thickness Class | PN + Structural Requirements | PN + Structural Requirements | PN + Structural Requirements |

Design Safety Factor | Experience-based | Clearly Defined | Clearly Defined | Referenced to ISO |

Internal Lining Requirements | Flexible | Cement mortar lining specified | Clearly Defined | Clearly Defined |

External Corrosion Protection | Optional | Zinc + Topcoat | Zinc or Equivalent | Similar to ISO |

Engineering Focus | Construction adaptability | Durability and corrosion | International applicability | Local engineering suitability |

Although nominal parameters can be approximately mapped, design logic and risk control priorities differ across standards, making simple parameter matching inadequate for engineering selection.

Table 3|Differences in Pipe Dimensions and Pressure Design and Their Engineering Impacts

Item | AWWA Standards | ISO / EN / GB Standards | Engineering Impact |

Outside Diameter | Not directly compatible with DN | Clearly mapped to DN | Connection compatibility risk |

Wall Thickness | Based on thickness class | Calculated by pressure rating | Structural verification differences |

Pressure Design | Experience-oriented | Theory-based | Safety factor discrepancies |

Interchangeability | Low | High | Procurement flexibility |

4. Practical Impacts of Standard Differences on Engineering

Table 4|Impacts of Standard Differences Across Project Stages

Project Stage | Main Impacts | Potential Risks |

Design | Diameter, wall thickness, connection selection | Design rework |

Procurement | Misunderstanding standards | Supply mismatch |

Construction | Installation practices differ | On-site adjustments |

Operation & Maintenance | Spare parts and replacement compatibility | Increased maintenance cost |

In practice, failing to define the applicable standard at the design stage often leads to interface incompatibilities and inconsistent technical documentation, increasing overall project coordination efforts.

5. Engineering Selection Recommendations and Standard Harmonization Trends

Table 5|Recommended DIP Standards for Different Engineering Scenarios

Engineering Scenario | Recommended Standards | Rationale |

International financing projects | ISO / EN | Widely recognized internationally |

North American municipal projects | AWWA | Compliance with local regulations |

Domestic municipal projects (China) | GB / ISO | Ease of approval and construction |

High-corrosion environments | EN / ISO | Clear corrosion protection requirements |

For detailed technical clauses, applicable engineering scopes, and certification requirements across international and national standards, as well as Tiegu’s compliance and certification status under different standard systems, please refer to our [Standards & Certifications] core page.

This page systematically summarizes mainstream standards and their practical engineering applications, providing targeted guidance for design selection, procurement, and compliance verification.

6. Conclusion

In summary, the US, European, and Chinese ductile iron pipe standards each have unique technical frameworks and engineering philosophies. These differences reflect long-term development within different engineering environments and management systems rather than simple technical superiority.

In practice, clearly defining the applicable standards at the project outset, thoroughly understanding their differences, and referencing authoritative standards documents for technical alignment is essential to reduce engineering risks and ensure the safety, economic efficiency, and long-term reliability of pipeline systems.

Sewage Pipe (Ductile Iron Sewage Pipe)

Sewage Pipe (Ductile Iron Sewage Pipe)

Special Coating Pipe (Ductile Iron Pipe with Special Coatings)

Special Coating Pipe (Ductile Iron Pipe with Special Coatings)

Dragging Pipe (Ductile Iron Dragging Pipe)

Dragging Pipe (Ductile Iron Dragging Pipe)